Passion times 4

Today Renault Group is at the forefront of a mobility that is reinventing itself. Wherever it is present, the Group is committed to satisfying customers whose mobility usages are changing radically.

How does it do this?

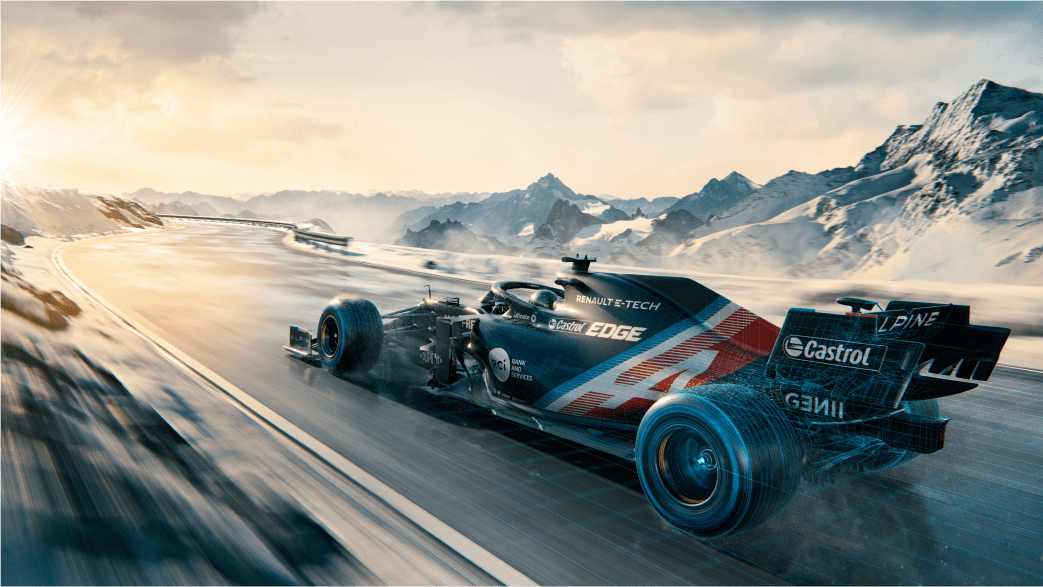

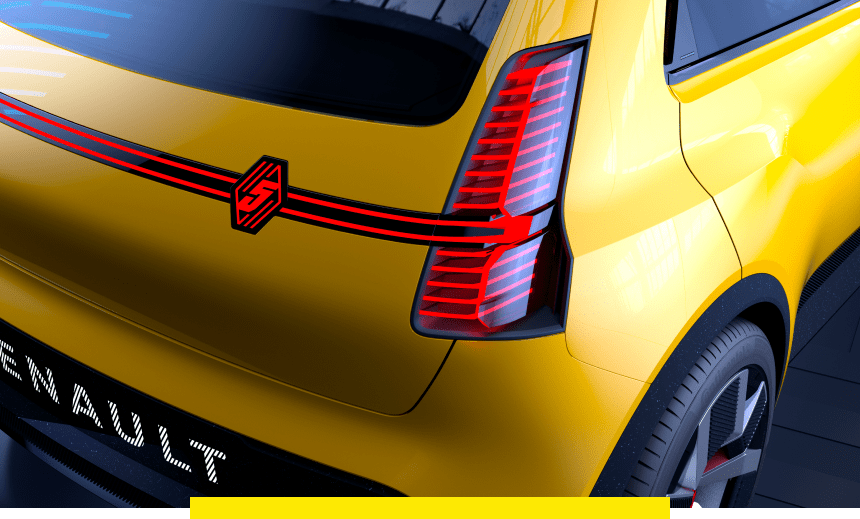

Thanks to Renault, Dacia, Alpine and MOBILIZE. Four complementary brands that are Renault Group’s strength internationally, with responses adapted to the many cultures, needs, markets and new usages of the automobile.

Innovating to build tomorrow's mobility

As a pioneer in sustainable mobility, Renault Group acts as a leader in the face of the environmental challenges, with the ambition to achieve carbon neutrality in Europe by 2040 and worldwide by 2050. Thanks to its electric models and its hybrid E-TECH and E-TECH Plug-in range, it offers concrete solutions that get lines moving. Market by market, from congested megacities to remote rural areas, from affordable vehicles to robotic taxis, the Group is building the mobility of the future, electric, connected and autonomous. With Mobilize, it goes beyond the bounds of the automotive industry, harnessing new growth drivers from the mobility and energy services and data management markets.

brands

Employees