Digital transformation seeks to make plants more efficient and 100% focused on customer satisfaction.

Digital innovation is founded on four drivers of disruption:

- real-time management of our plants and their supply chain

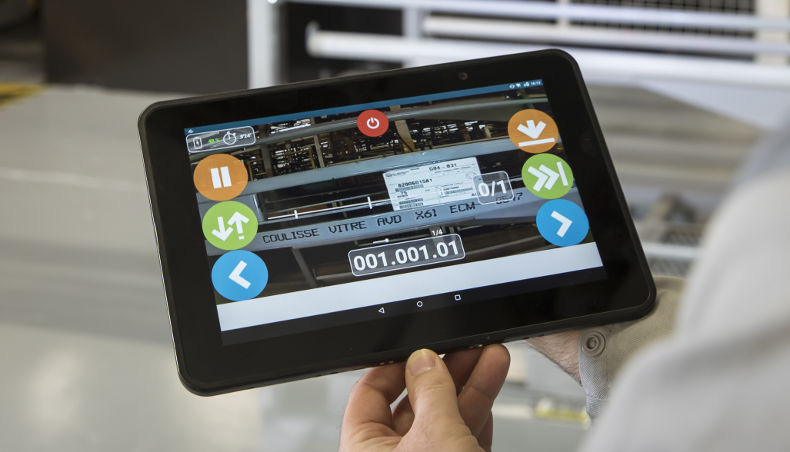

- total traceability (full track and trace)

- predictive and corrective maintenance to capture manufacturing data so as to be able to anticipate breakdowns

- connect employees with effective and mobile tools

________

How can “Full Track and Trace” be defined?

“Full Track and Trace” provides access to a product's composition history. From the production line to customer distribution. It also makes it possible to trace the steps of the production journey: provenance of components, suppliers, storage locations, logistics, etc. “Full Track and Trace”, an essential resource for the factory of the future, affects our plants and all industrial sectors. Whether it is car parts, food products or medicines that are being tracked, this project is in line with our quality approach. It improves the identification of products. It also aims to standardize the tracing of products and link a part and a manufacturing process to a vehicle...

We are also working on developing an IT platform: this data model benefits all our industrial sites and breaks business data out of silos.

Can you give us examples of what was achieved in 2018?

The “Full Track and Trace” platform allows users to view, for our Valladolid plant in Spain, all the serial numbers of our engine parts, their manufacturing journeys, and the associated process parameter values.

At Maubeuge, we automatically track the movements of packages containing the parts fitted to our vehicles.

We have also put in place traceability of prototype parts for our Vehicle Prototype Development Center at the Guyancourt Technocentre. This means we know instantly which precise part is fitted to a given test vehicle to ensure that it is compliant.

The “Full Track and Trace” project therefore helps achieve quality, logistical and industrial aims.

What are the benefits for customers and for the Group?

Customers want an increasingly customized vehicle equipped with new technologies. “Full Track and Trace” allows us to manage this wide range of offers.

“Full Track and Trace” is also a way for the company to drive economic effectiveness. Having access to location data allows us to track supply logistics in real time, save time on inventories, and ensure that we stock only what is necessary. The data we hold on every single part, its history, can be used in engineering to improve the design of a part, or in after-sales to analyze its behavior.